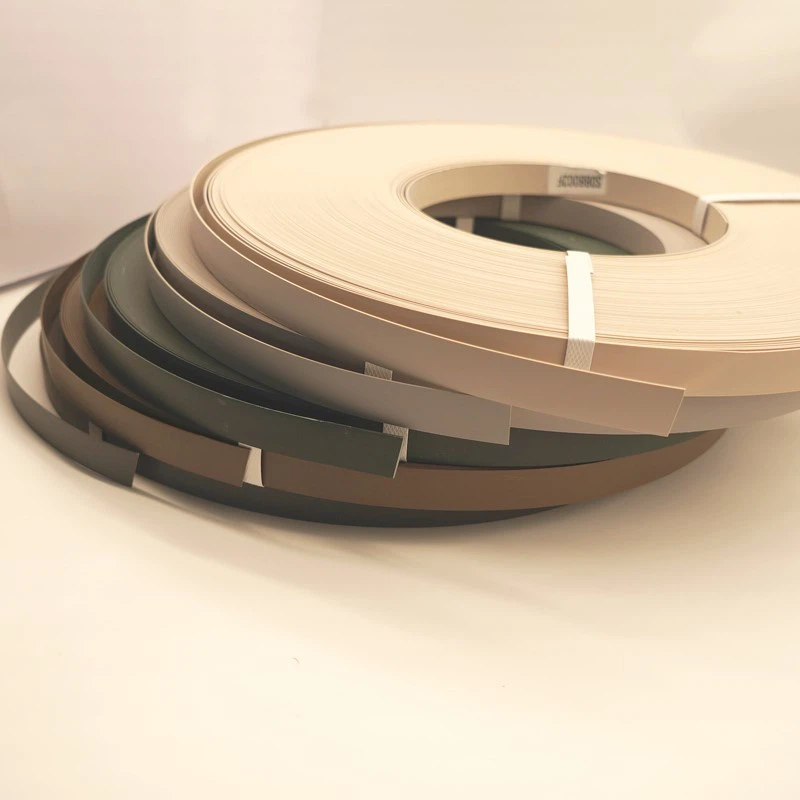

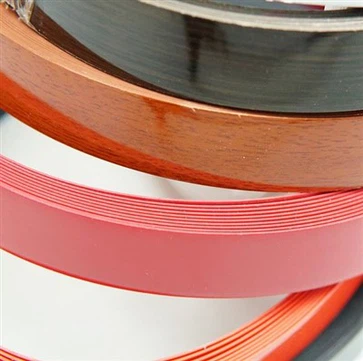

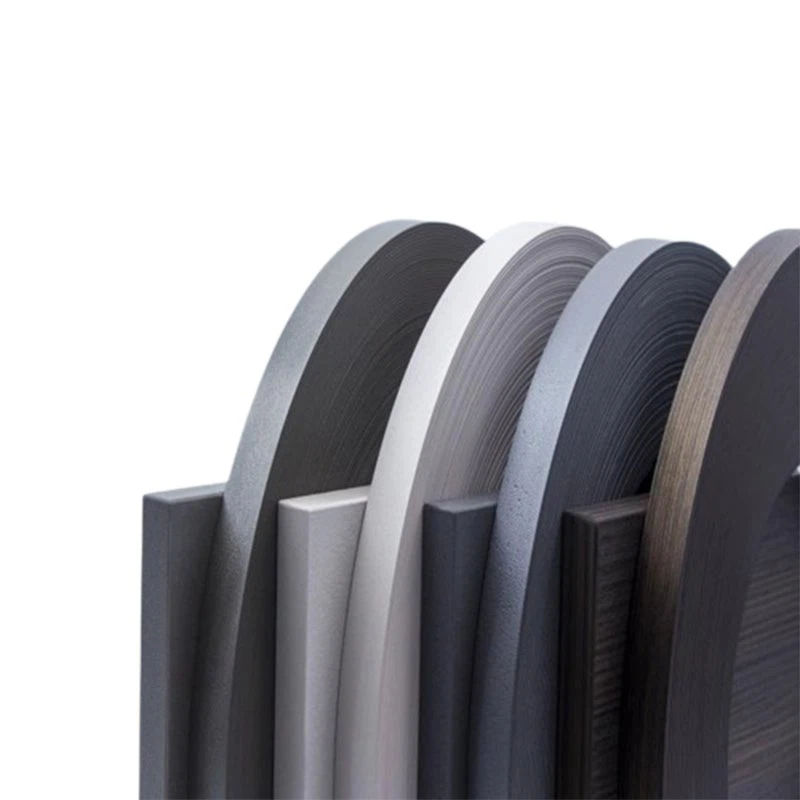

In general, manufacturers use PVC edge banding to improve the problem of burrs when producing and decorating panel furniture. The use of decorative strips directly affects the aesthetics and practicality of furniture. In order to meet the requirements of decorative and protective furniture, it is necessary to complete the edge sealing work of furniture under ideal usage conditions. So, what is the ideal environment for using edge banding?

1. Temperature

The ideal operating temperature for edge banding is 190~210 ℃, but due to different brands and models of hot melt adhesives, an environment of 120~190 ℃ can also be selected according to their characteristics. As the temperature increases, the bonding strength of the edge banding will also improve, so it is recommended to use high-temperature hot melt adhesive to achieve the ideal edge banding effect.

2. Edge angular velocity.

If the thickness of the edge banding strip is less than 0.6mm, the edge banding strip will experience softening and stretching during the edge banding process. The occurrence of deformation and other phenomena is mainly due to the slow edge banding speed and the long melting and retention time of hot melt adhesive. To address this phenomenon, the edge banding speed can be accelerated by using high-speed conveyor belts.

The factors that affect edge banding are not limited to the above two aspects. As far as edge banding technology is concerned, an ideal edge banding environment should be selected and edge banding rules should be followed in order to effectively solve furniture edge banding problems.