Hey there! As a supplier of 3mm PVC edge banding, I often get asked about how our product performs in cold temperatures. It's a valid question, especially for those who are working in environments where the mercury drops. So, let's dive right in and explore the ins and outs of 3mm PVC edge banding when the cold hits.

Understanding 3mm PVC Edge Banding

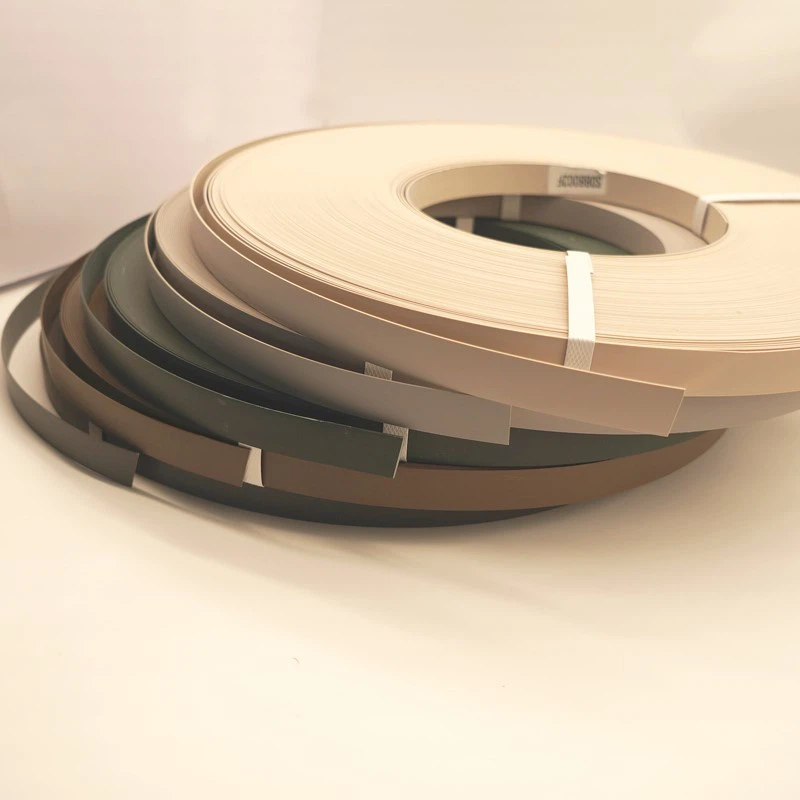

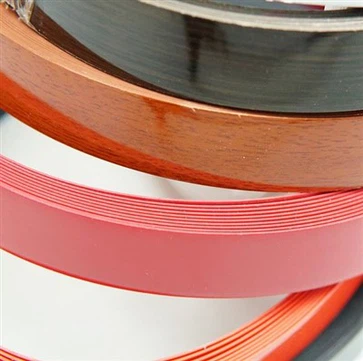

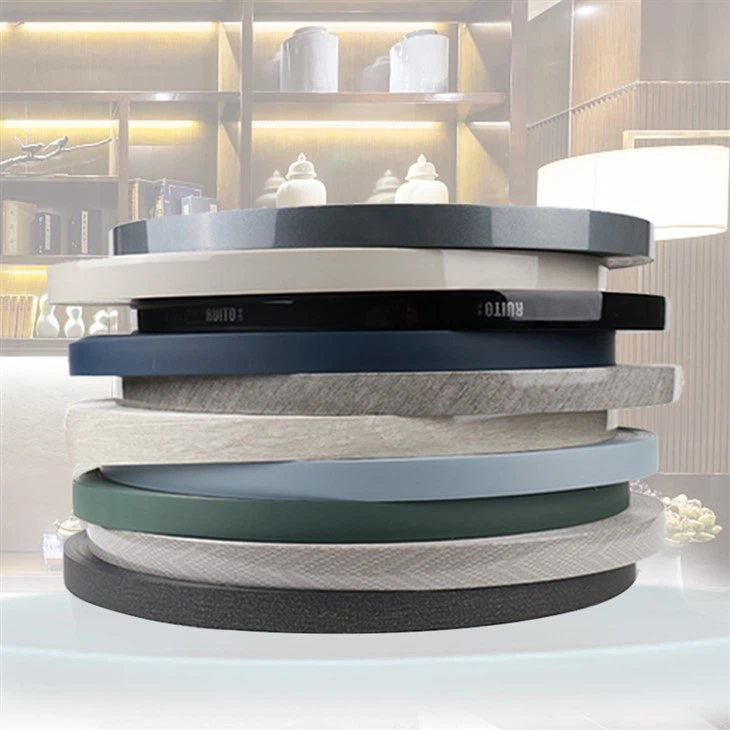

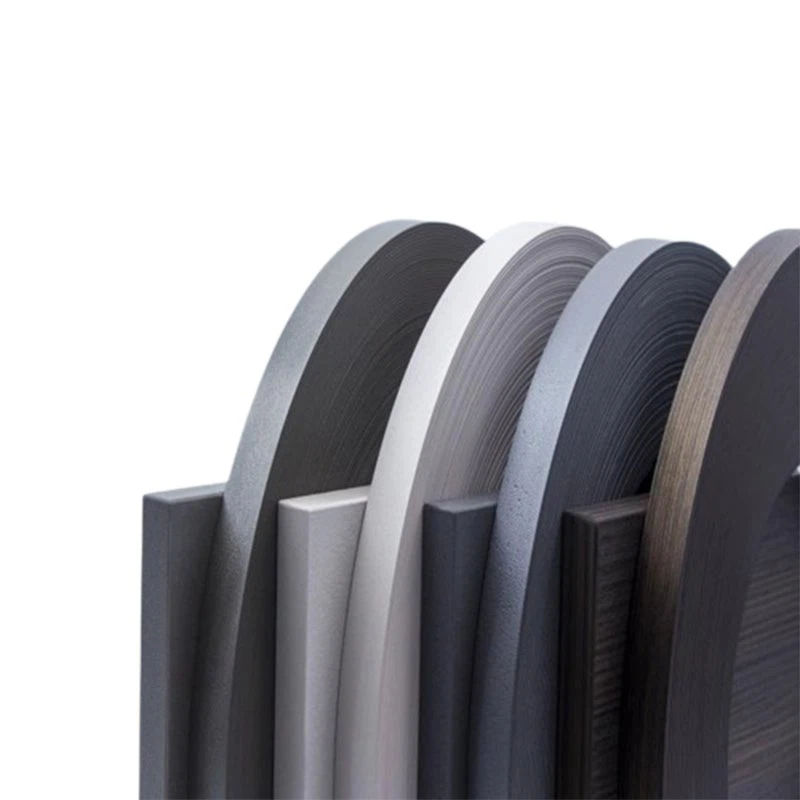

First off, let's quickly go over what 3mm PVC edge banding is. PVC, or polyvinyl chloride, is a synthetic plastic polymer that's widely used in various industries. Our 3mm PVC edge banding is a thin strip of PVC material that's used to cover the exposed edges of furniture, cabinets, and other wood - based products. It not only enhances the appearance of the product but also provides protection against moisture, scratches, and wear. You can learn more about it on our 3mm PVC Edge page.

How Cold Temperatures Affect PVC

PVC, like many materials, is affected by temperature changes. When the temperature drops, PVC becomes more rigid. This is due to the molecular structure of PVC. In cold conditions, the molecules in PVC slow down and become more closely packed together, reducing the material's flexibility.

For our 3mm PVC edge banding, this change in flexibility can have several implications. One of the most noticeable effects is on the installation process. In cold temperatures, it can be more difficult to bend and shape the edge banding around corners and curves. You might find that it's more prone to cracking or breaking if you try to force it into a tight bend.

Installation in Cold Weather

If you're planning to install 3mm PVC edge banding in cold temperatures, there are a few things you can do to make the process smoother. First, try to warm up the edge banding before installation. You can do this by bringing it into a warmer room for a few hours before you start the job. This will make it more flexible and easier to work with.

Another tip is to use a high - quality adhesive that's designed for cold - weather applications. Some adhesives can become less effective in cold temperatures, so choosing the right one is crucial. You can also use a heat gun sparingly to gently warm the edge banding during installation, but be careful not to overheat it, as this can damage the PVC.

Performance After Installation

Once the 3mm PVC edge banding is installed, it will continue to be affected by the cold. One potential issue is delamination. In very cold conditions, the adhesive that bonds the edge banding to the substrate can lose its grip, causing the edge banding to peel away. This is especially true if there are any gaps or air bubbles between the edge banding and the substrate during installation.

However, if the installation is done correctly and the right adhesive is used, our 3mm PVC edge banding can still provide good performance in cold temperatures. It will continue to protect the edges of the furniture or cabinet from moisture and physical damage. You can check out our 3mm PVC Edge factory page to learn more about the quality control measures we take to ensure our products perform well in different conditions.

Durability in Cold Climates

In terms of long - term durability, our 3mm PVC edge banding can withstand cold climates quite well. PVC is a relatively stable material, and as long as it's not exposed to extreme cold for extended periods, it should maintain its integrity.

However, if the edge banding is constantly exposed to freezing temperatures and large temperature fluctuations, it may experience some wear and tear over time. The surface of the PVC may become dull or brittle, and it may be more prone to cracking. But overall, with proper care and installation, it can last for many years in cold environments.

Applications in Cold - Related Industries

Our 3mm PVC edge banding is suitable for a variety of applications in cold - related industries. For example, it can be used in the construction of cold storage units and refrigerated cabinets. In these applications, the edge banding provides a protective barrier against moisture and helps to maintain the structural integrity of the cabinets. You can find more information about using our edge banding for such applications on our Vinyl Edging for Plywood page.

Tips for Maintaining 3mm PVC Edge Banding in Cold

To keep your 3mm PVC edge banding in good condition in cold temperatures, there are a few maintenance tips you can follow. First, avoid exposing it to direct contact with ice or snow. If possible, keep the area around the edge banding dry. Moisture can seep under the edge banding and cause damage, especially in cold conditions.

Regularly inspect the edge banding for any signs of damage, such as cracks or peeling. If you notice any issues, address them promptly. You may need to replace the damaged section of the edge banding to prevent further problems.

Conclusion

In conclusion, while cold temperatures do have an impact on 3mm PVC edge banding, with the right approach, it can still be a great choice for your projects. By understanding how cold affects PVC, taking the necessary precautions during installation, and following proper maintenance procedures, you can ensure that your 3mm PVC edge banding performs well in cold conditions.

If you're interested in purchasing our 3mm PVC edge banding or have any questions about its performance in cold temperatures, don't hesitate to reach out. We're here to help you make the best choice for your needs.