Which one works better, PVC edge banding or ABS edge banding?

The main function of edge banding is to seal the cross-section of the board, to prevent environmental and adverse factors (mainly moisture) from damaging the board during use, and to prevent the volatilization of formaldehyde inside the board, together achieving the purpose of decoration. The common types of edge banding are PVC and ABS, with ABS having a better edge banding effect,

The comparison of the effects of PVC and ABS edge banding is as follows:

1. ABS edge banding does not add any fillers (such as calcium carbonate) during the production process, so the rounded corners after trimming are very smooth and bright, and together with the appearance, they have strong impact resistance; PVC is prone to white edges during edge trimming due to the addition of high carbonate fillers.

2. ABS edge banding only shows shortening at high temperatures of 99 degrees Celsius; However, PVC already exhibits shortened joints at 70 degrees, which can lead to issues such as deformation and expansion of the board.

3. ABS edge banding has strong resistance to chemical corrosion and is constantly renewed over time. Coffee, soy sauce, alcohol, etc. will not cause any damage to its appearance; PVC, on the other hand, is prone to aging and staining.

4. ABS edge banding without irritating odor; PVC has a plastic odor.

5. ABS edge banding can be directly burned at high temperatures without air pollution; PVC produces dioxin gases, leading to the occurrence of the greenhouse effect.

Compared to PVC edge banding, ABS edge banding has a better effect, but the cost is also higher. According to the different needs of shopping malls, PVC edge banding is more widely used.

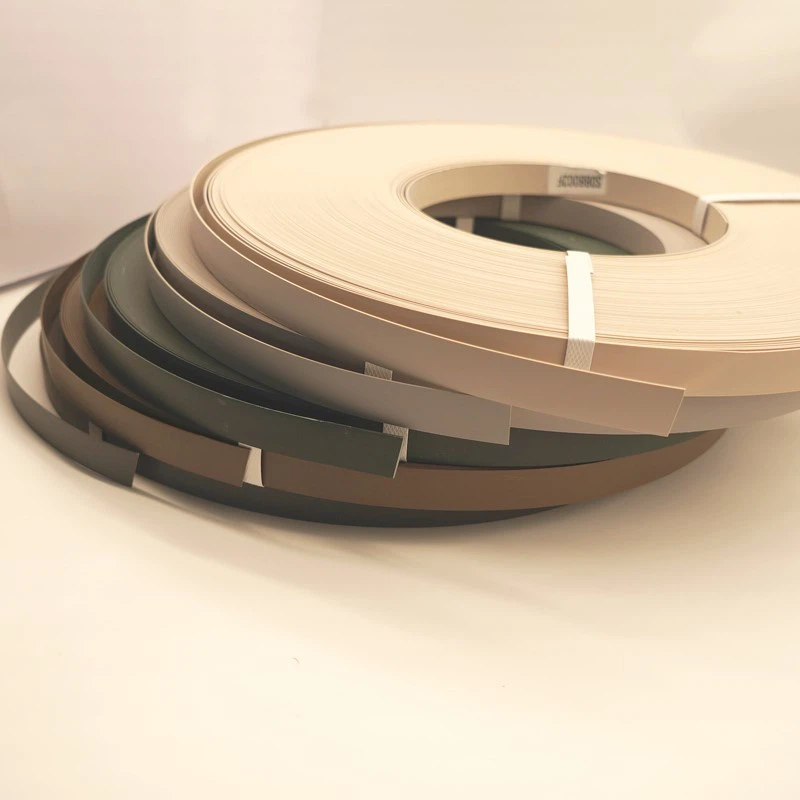

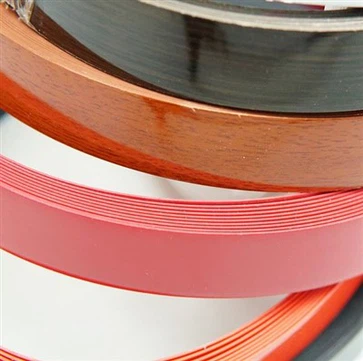

PVC Edge Banding

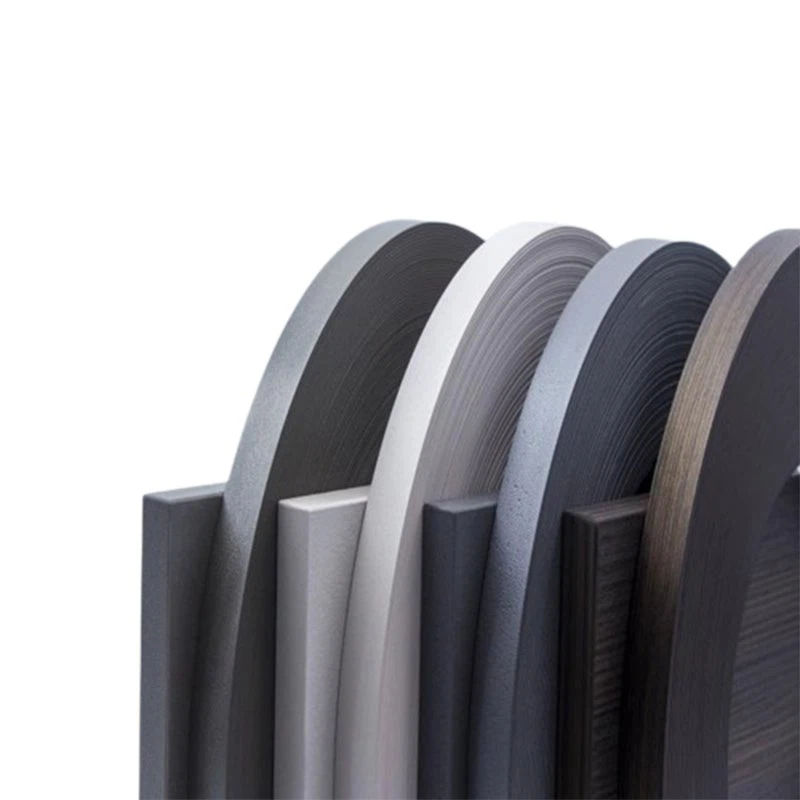

ABS Edge Banding

PP Edge Banding

Metallic Edge Banding

Acrylic Edge Banding

Digital Printing Edge Banding

Laser Edge Banding

Veneer Edge Banding

Melamine Edge Banding

Pre-Glued Edge Banding

Profile Edge Banding

Plastic Screw Caps