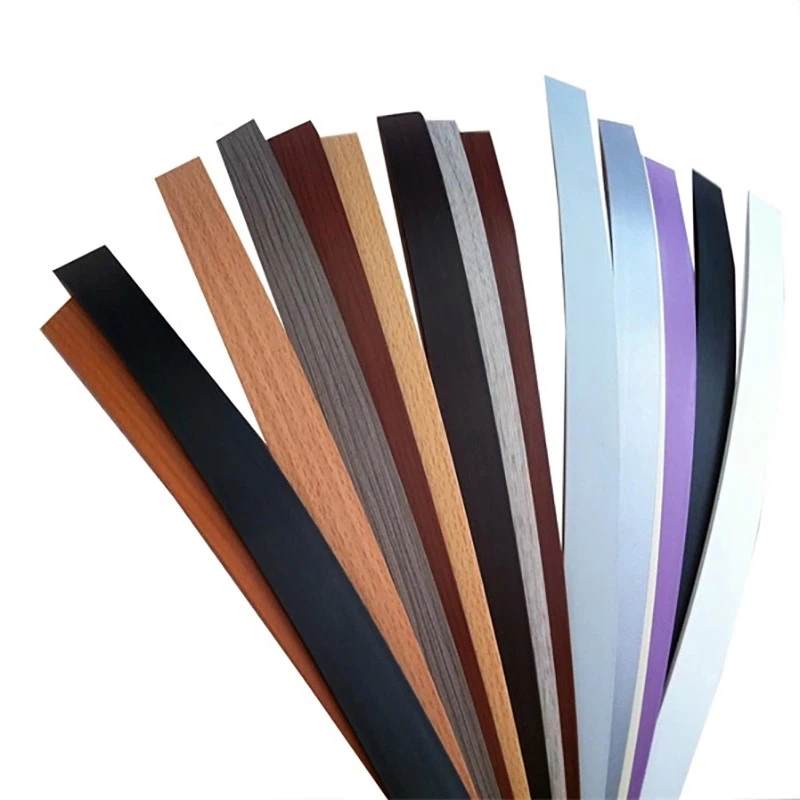

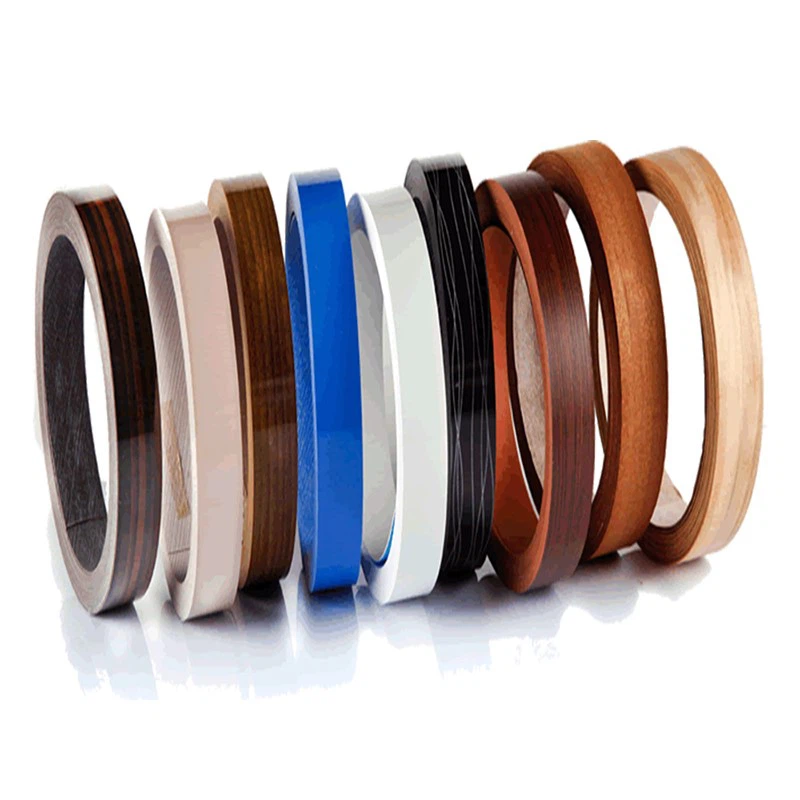

Thick pvc edge banding are made of polyvinyl chloride resin and can be processed into wood grain, plain color, or two-color. It is used for medium and low-end furniture. It is relatively soft and easy to construct. Many carpenters use this material to seal edges when making furniture.

Thick pvc edge banding are made of polyvinyl chloride resin and can be processed into wood grain, plain color, or two-color. It is used for medium and low-end furniture. It is relatively soft and easy to construct. Many carpenters use this material to seal edges when making furniture.

What are the methods of edge sealing?

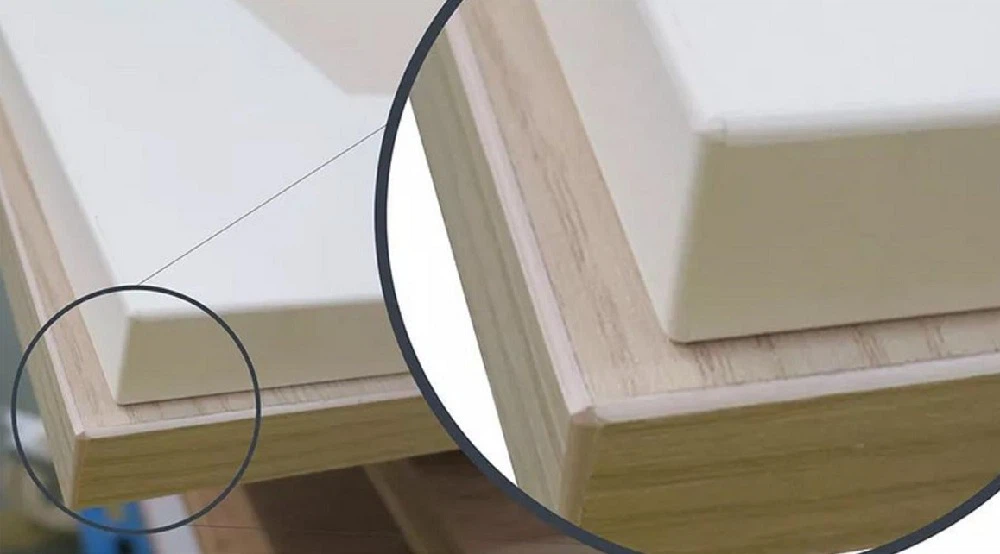

When it comes to decorating our homes with custom cabinets, we want the best quality possible. This is why carpenters often use paint-free boards finished with edge sealing technology. These sealing methods are critical to ensuring the longevity and strength of the final product, and two commonly used techniques are glue sealing and U-shaped buckles.

By taking the time to properly seal the edges of your custom cabinets, we can ensure that they are both beautiful and functional. It is important to remember that even the smallest details, such as edge sealing, can have a big impact on the overall quality of our homes. So, let's embrace the craftsmanship of the carpenter and enjoy the beauty and functionality of our custom cabinets for years to come!

Two characteristics of pvc edge tapes

1) Cost-Effectiveness: Its cost is low compared to other types of edging materials. This makes them an excellent choice for businesses looking to save on production costs without sacrificing quality.

2) Easy to work with: its flexibility of these thick pvc edge tapes allows them to be easily cut, shaped and applied to a variety of surfaces, providing a seamless finish that looks professional and polished.

three main functions of edge sealing banding:

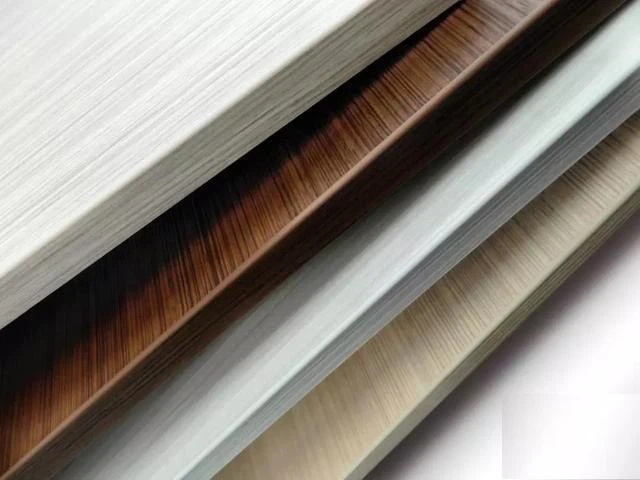

1) Edge banding plays an aesthetic and decorative role in the furniture products. It makes the edges of the board look clean, neat and polished.

2) Edge banding is waterproof and moisture-proof. Wood absorbs moisture easily, causing swelling, warping, and cracking. Edge sealing tape creates a barrier that prevents moisture from penetrating the edge of the board, thereby reducing the risk of damage.

3) Edge banding effectively prevents the release of formaldehyde. Formaldehyde is commonly used in the production of wood products, and edge banding ensures that formaldehyde is safely contained within the board, thereby reducing the risk of human exposure to formaldehyde.

How to choose pvc edge banding

1) Check whether the side of the board is even after trimming. If there are jagged edges, the following reasons may occur: the trimming knife is too blunt, the edge banding strip is too hard, or the edge banding strip contains too much calcium carbonate.

2) Check whether the saw surface of the board is flat. If the upper and lower saw blades are of different specifications when sawing the board, there will be small steps on the saw surface when sawing the board, which will affect the edge sealing.

Edge banding sealing processing environment

1) The temperature cannot be lower than 18℃.

The temperature of the workshop where edge banding sealing is processed cannot be too low. The hot melt adhesive will not cool down too quickly and cannot be edge banded and glued according to the process parameters.

2) Do not place edge sealing equipment in vents or gates. Cold wind will affect the quality of edge sealing.

FAQ

Q1: What's your output?

A: 100,000 meters per week

Q2: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. And for mass production it takes 15-20 days.