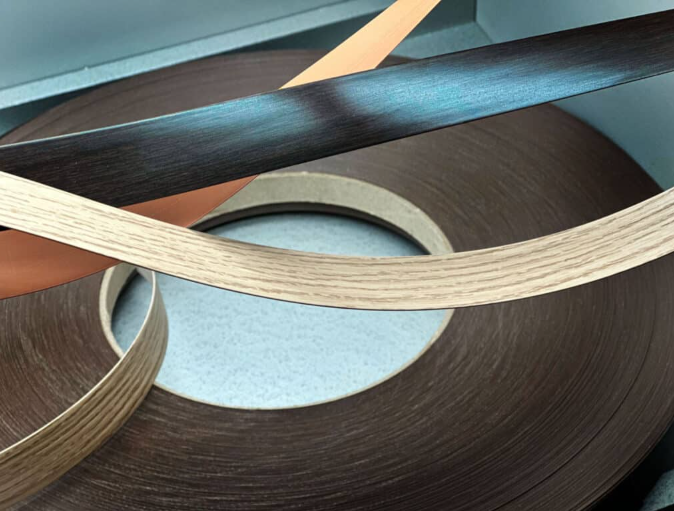

Furniture edge banding is a material that protects, decorates, and beautifies the cross-section of furniture panels. It can make a piece of furniture show a clear and colorful overall effect of wood grain.

The main component of PVC edge banding is polyvinyl chloride, which is made by mixing, rolling, vacuum molding and other processes. The product is widely used in furniture, office, kitchenware, teaching equipment, civilian laboratories, etc. The thickness ranges from 0.3 to 3mm, and the width ranges from 12mm to 80mm. The product has the following main characteristics: smooth surface, no foaming, no pulling lines, moderate glossiness, smooth surface and back, uniform thickness, consistent width, reasonable hardness, high elasticity, good quality, strong wear resistance, edge sealing after trimming, side color close to surface color, no whitening, good glossiness, and overall color coordination of furniture products.

The main function of edge banding is to seal the cross-section of the board, to prevent environmental and adverse factors (mainly moisture) from damaging the board during use, prevent formaldehyde volatilization inside the board, and achieve a decorative and aesthetic effect.